Online shopping has been supplanting brick-and-mortar stores for decades. Then, during pandemic lockdowns, they relied on e-commerce even more for everyday items. Consumers expect free, fast delivery for everything they buy. Traditional distribution methods can’t keep pace with demands. Enter: micro-fulfillment centers.

The Micro-fulfillment Strategy

Micro-fulfillment is emerging as a competitive approach to last-mile distribution. These 5,000 to 20,000 square foot warehouses are accessible to urban areas and packed with high-demand products. Proximity to the final consumer means fast home delivery and curbside pick-up. The beauty of the micro-fulfillment strategy is scalable, modular logistics that you can configure based on demand.

FAQ: How do you build a micro-fulfillment center?

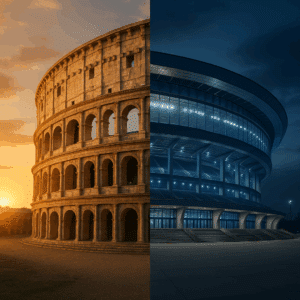

Strategic layout and design are essential elements of building an efficient micro-warehouse. While some facilities are built from the ground up, converting abandoned big-box stores is usually more cost-effective. Therefore, scouting the right location is critical. In addition, you need the right-sized building close to the final consumers. That being said, the quality of the building is a decisive factor in avoiding maintenance and repairs.

Equipping a fulfillment business depends on specific services. For example, a grocery fulfillment center would need ambient, cool, and frozen sections. Likewise, strategic arrangements of shelving and digital signage create conducive thoroughfares for mobile robots and drones. In addition, the facility needs traditional pick-and-pack equipment such as forklifts, scales, packing materials, trucks, and safety gear.

Design Trends for Micro-warehouses

When it comes to micro-fulfillment, the “micro” part is relative. The smaller sizes offer big advantages. For example, smaller footprints are available near densely populated urban areas. However, tight spaces need an optimized strategy to maximize efficiency. Lately, we have been seeing three significant trends emerge in micro-warehouse design.

1. Automation

Automated technology fulfills orders quickly and efficiently. For example, drones and mobile robots eliminate repetitive aspects of picking, such as scanning and selecting products of uniform size. For more complex orders, automated shuttles assist human pickers and increase productivity.

2. Connectivity

Satellite and 5G networks allow real-time order handling throughout the supply chain. In addition, connected sensors and smart shelves monitor temperature and manage inventory within each facility.

3. Digitization

Cutting-edge software offers logistics solutions for managing micro-fulfillment centers. In addition, tracking and mobile apps meet customers’ on-demand expectations.

Cost and ROI of Micro-fulfillment Centers

Starting a micro-fulfillment operation requires an upfront investment. The start-up expenses vary depending on square footage and location. However, the typical figure is between $3 million – $5 million initial expenditure. Then, most start seeing a return on investment (ROI) after two to five years of operation.

The size and efficiency of micro-warehouses save money compared to traditional, large-scale fulfillment centers. For example, the relatively smaller footprints mean lower rents and advantageous locations. Being closer to the ultimate destination reduces last-mile delivery expenses. In addition, using automation vastly increases efficiency and profits compared to manual picking.

According to a report from Chainalytics, automation provides faster throughput at lower costs. Robots are more accurate and move an average of 600 units per hour (UPH) at the cost of $3-$6 per order. In contrast, manual fulfillment costs $10-$15 per order and moves at a rate of about 100 UPH.

Smart Strategies for Micro-fulfillment Centers

The covid pandemic has revealed significant flaws in the supply chain. So, sellers need speedy, scalable, and sustainable solutions to stay competitive in the e-commerce market. To be successful, a micro-fulfillment operation requires an optimized layout and design. We are experienced architects who can manage the design and construction of micro-fulfillment centers from start to finish. So, let’s strategize—call 201-939-1446.